Analyzing the role of nickel surfaces as pathogen inhibitors

Abstract

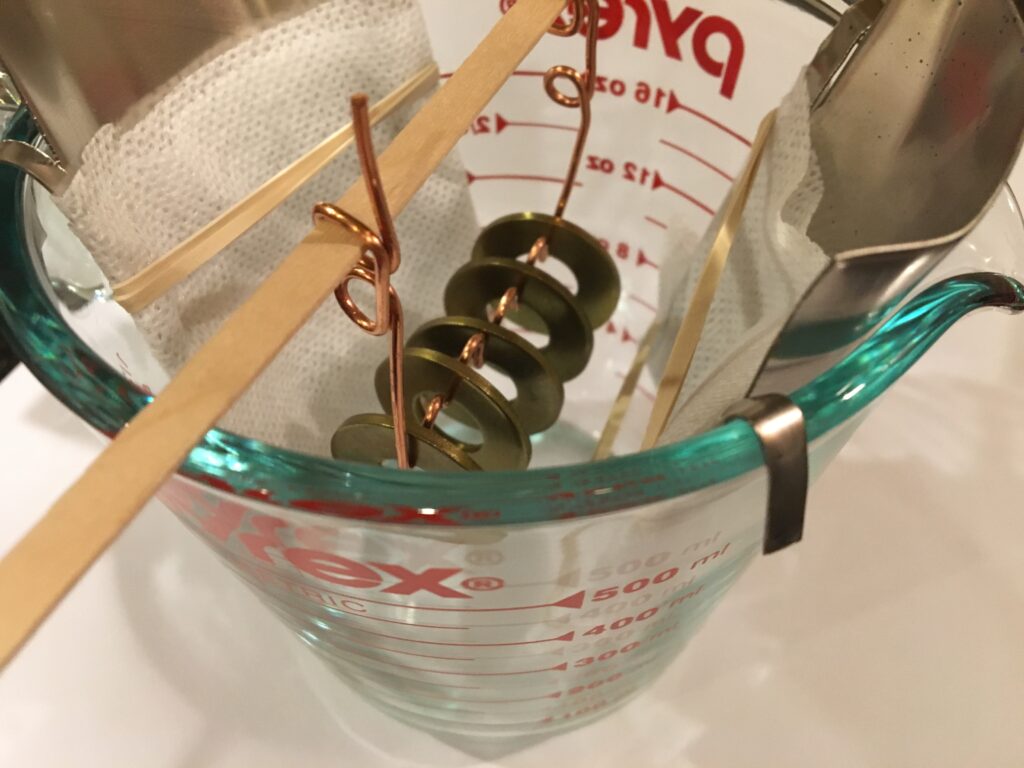

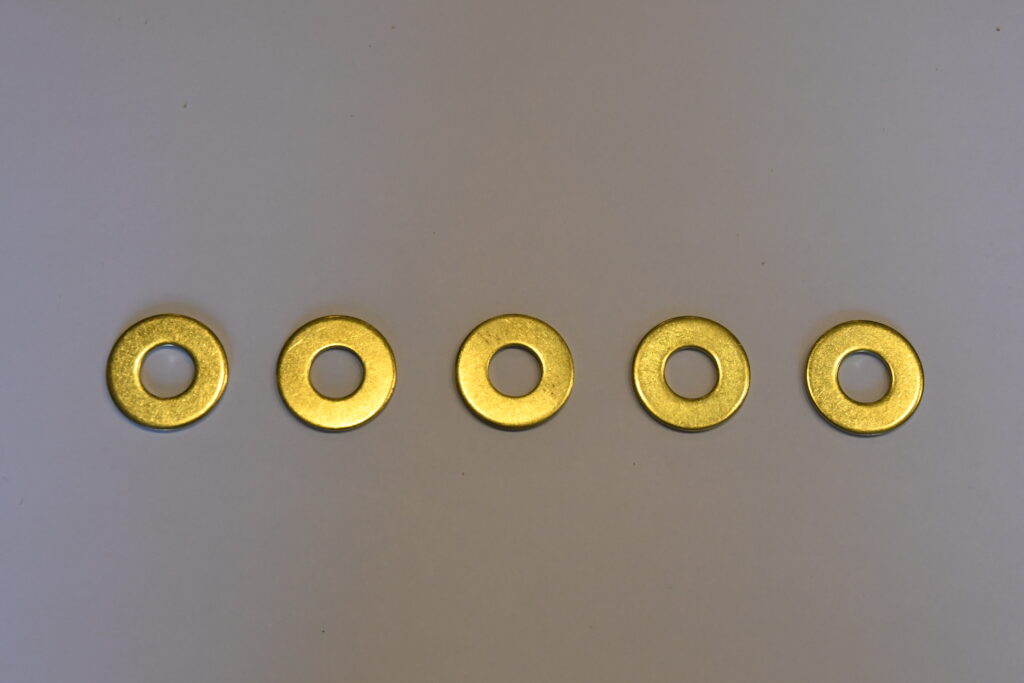

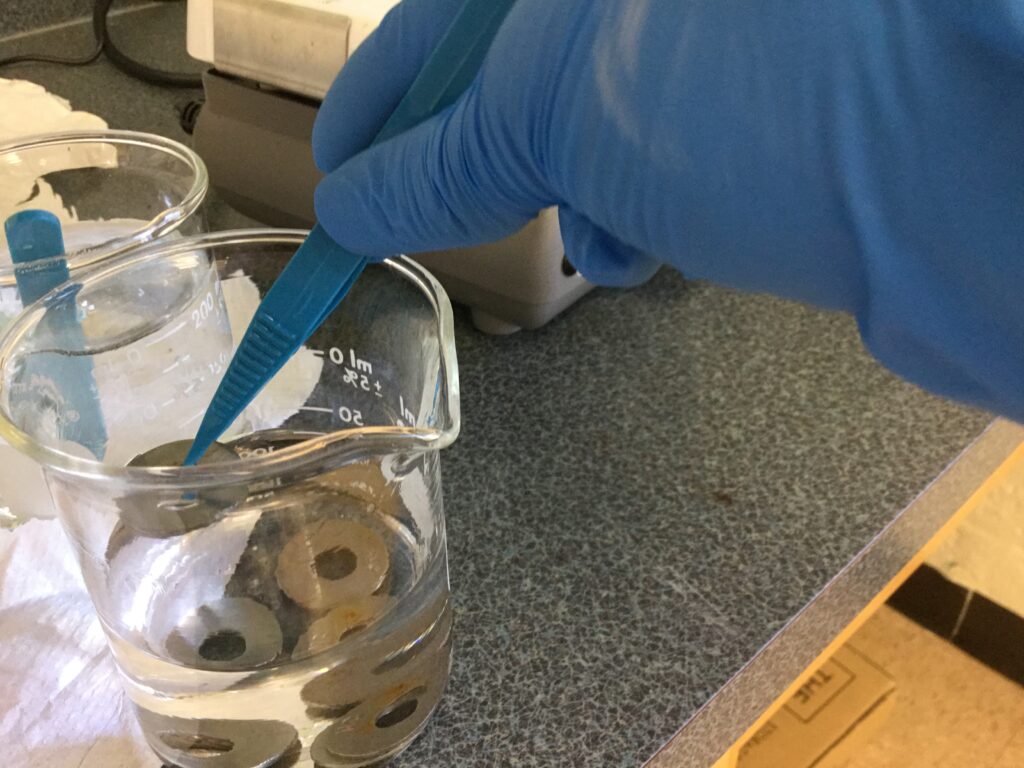

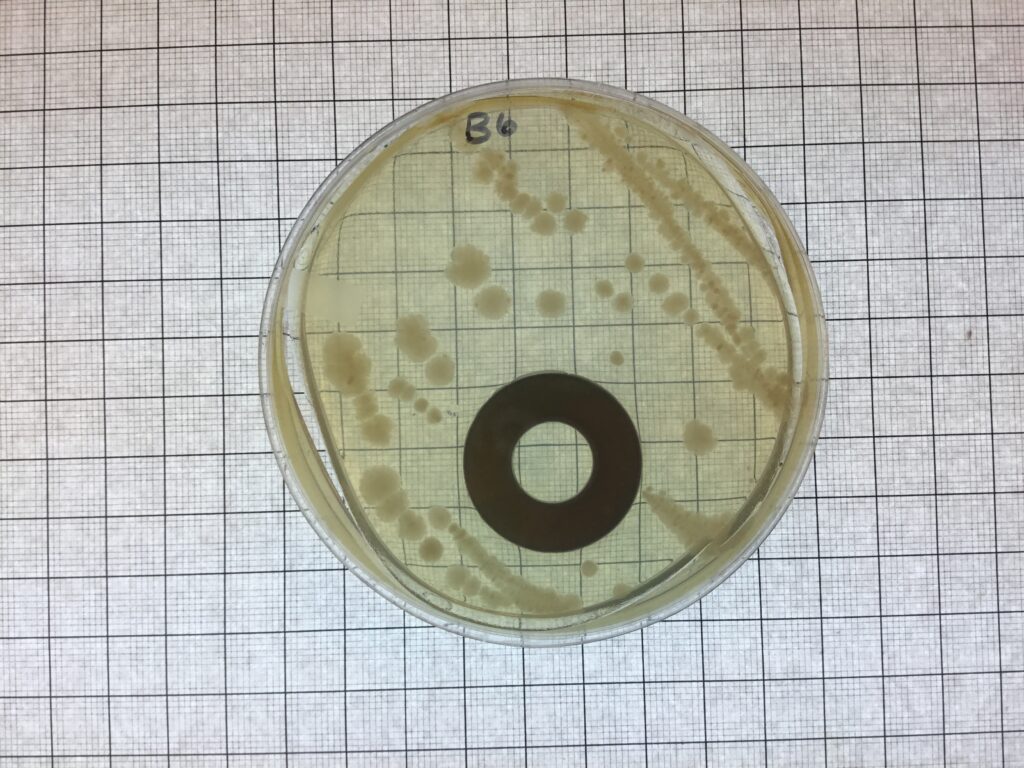

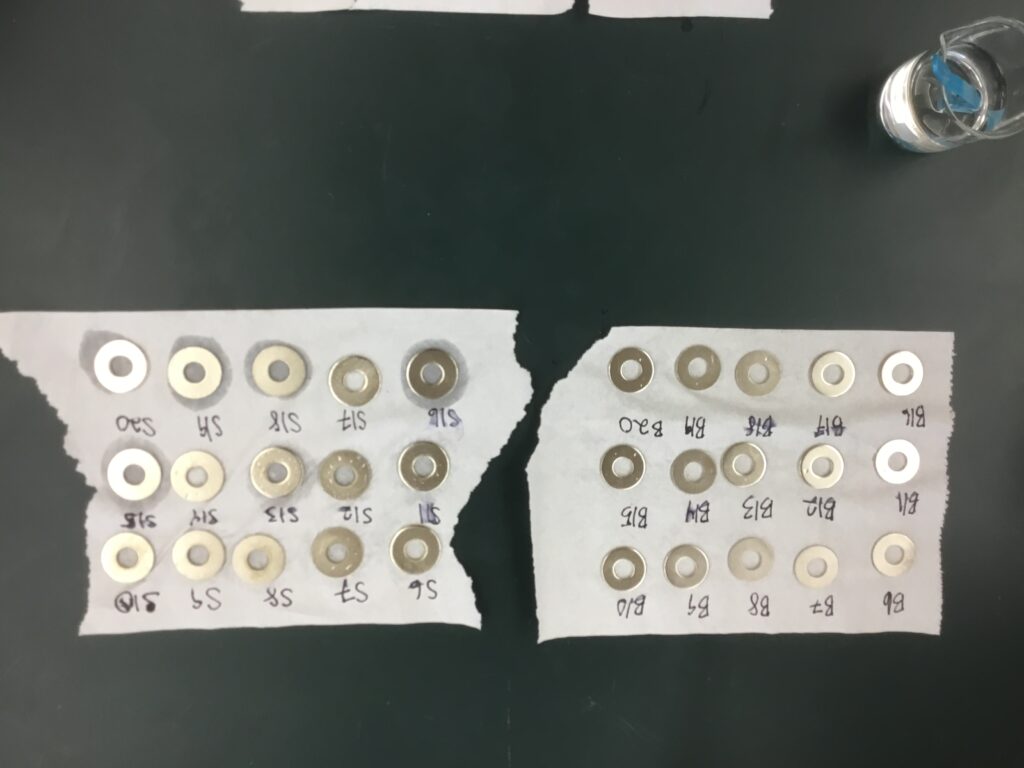

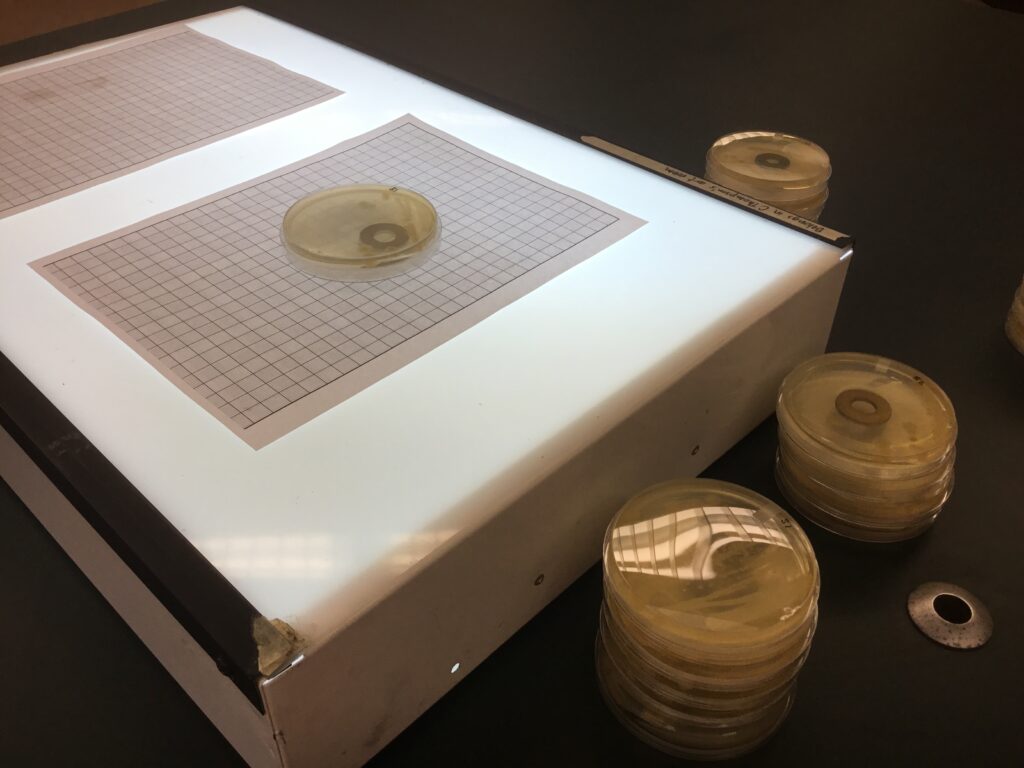

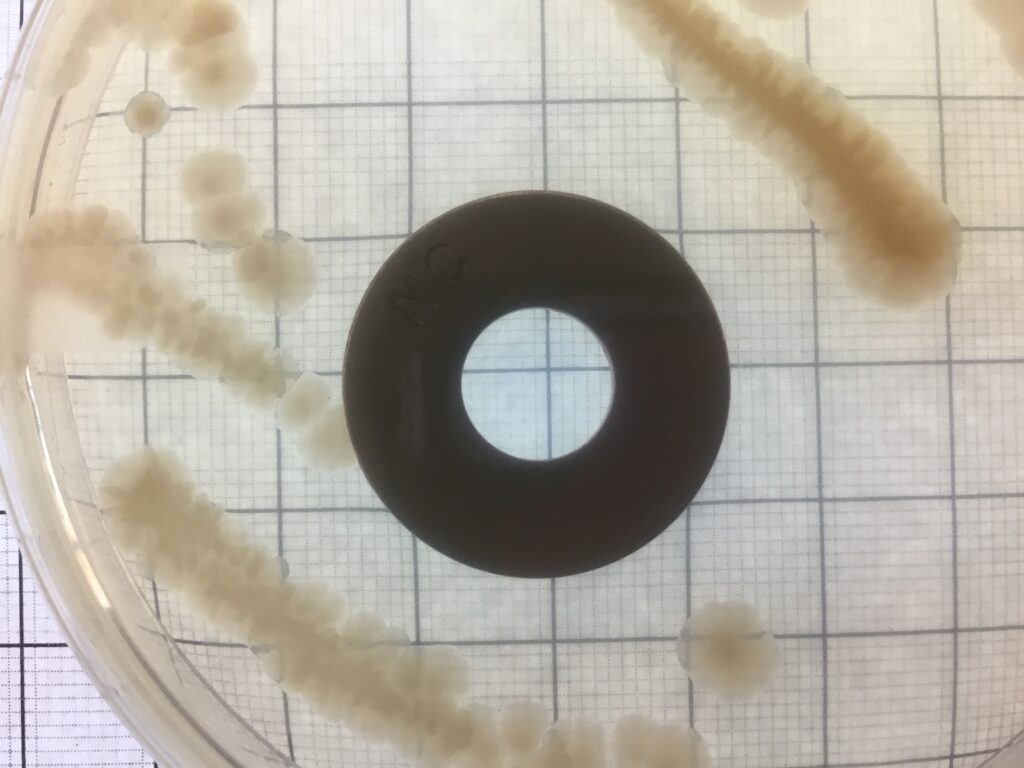

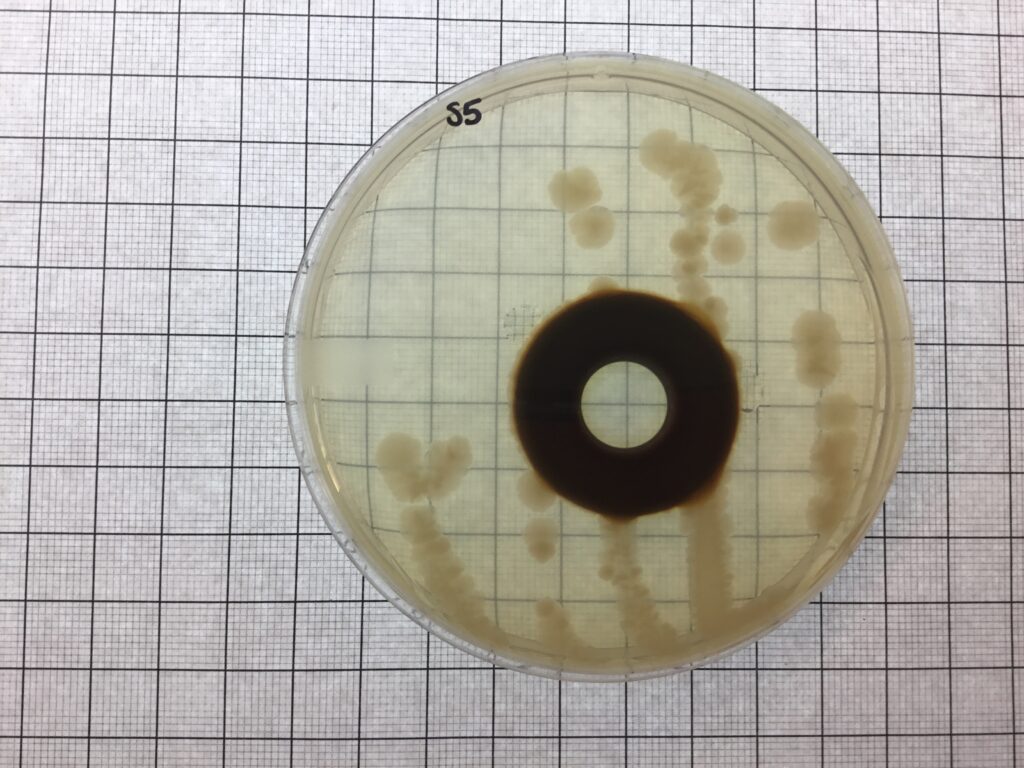

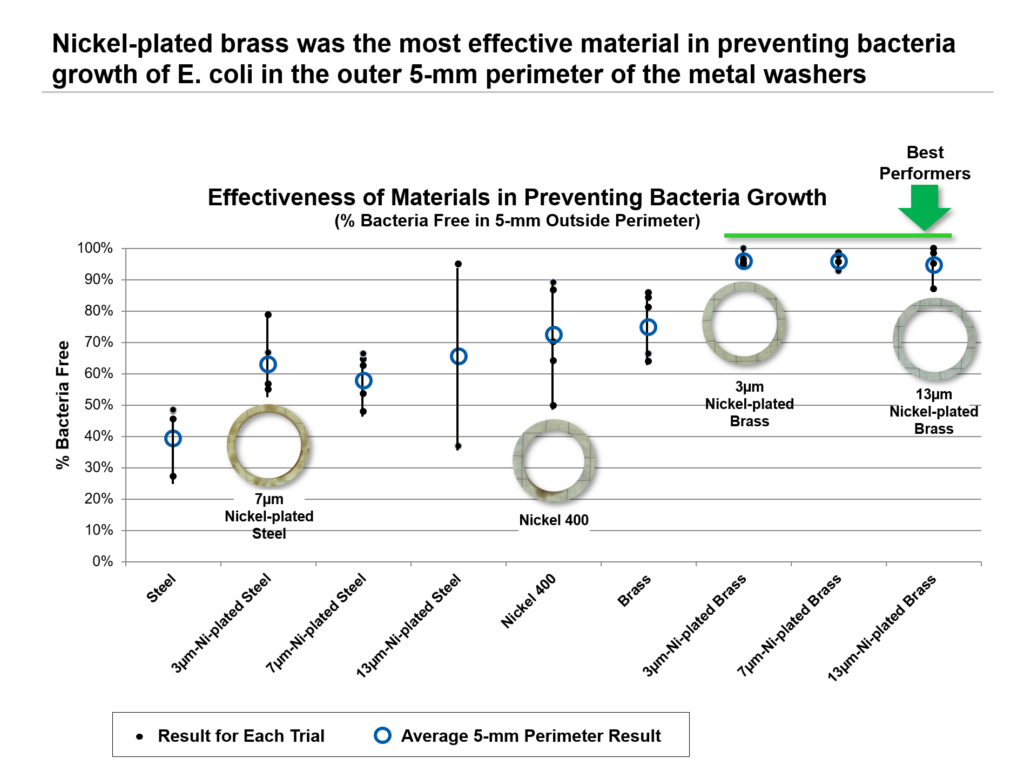

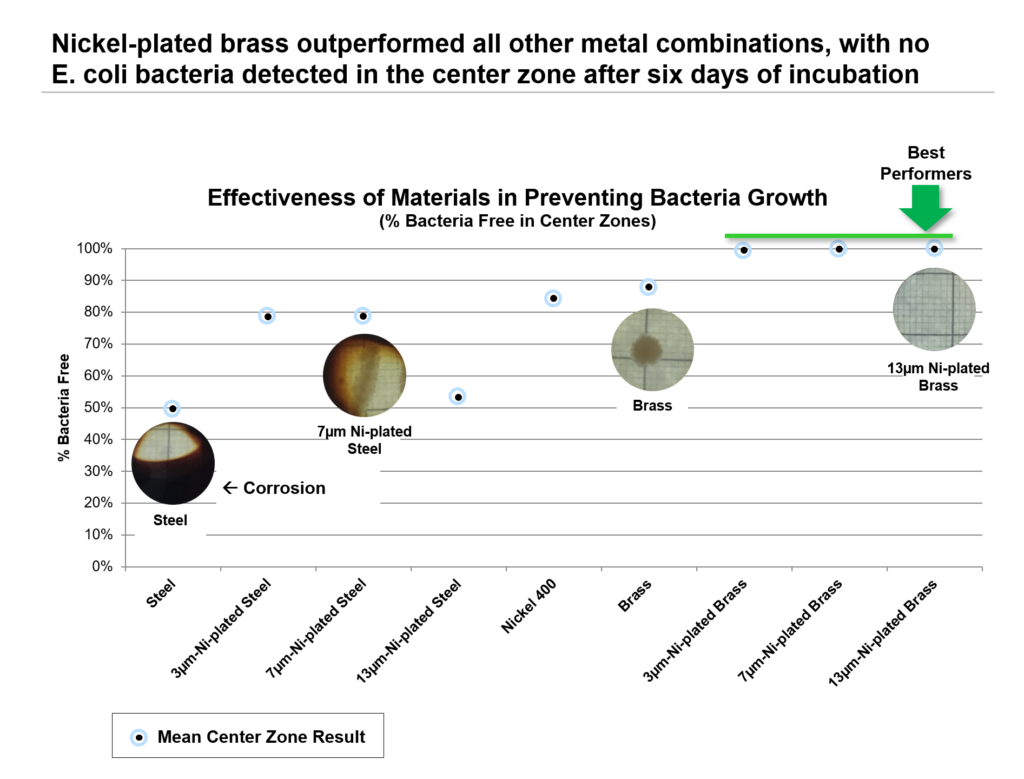

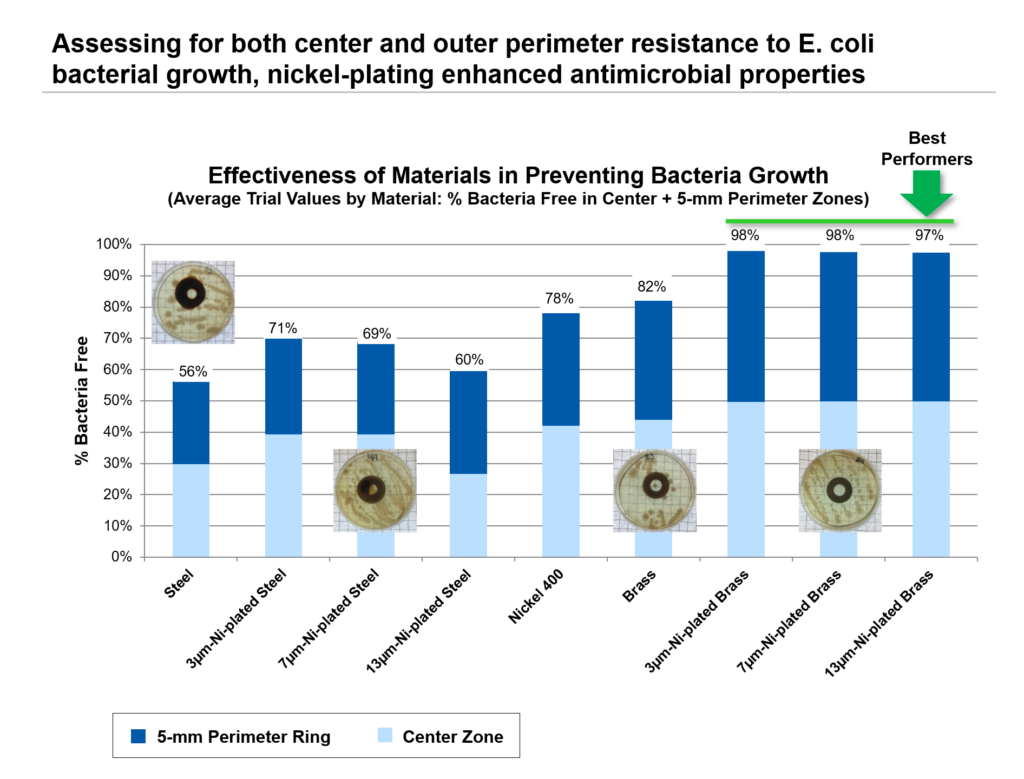

As individuals come into contact with touch surfaces each day—doorknobs, handrails, ATM machines—these surfaces are effectively turned into transmission sites for microbes. Approximately 80% of infectious diseases in the United States are transferred through in this manner. In Europe, nearly 40,000 deaths each year and €7 billion in economic losses are directly caused by healthcare-associated infections. Most touch surfaces are made from materials that sustain bacteria growth, such as stainless steel and aluminum. Motivated by the copper industry promoting antimicrobial benefits of copper, this author tested the effectiveness of 12 metals at resisting E. coli bacteria growth and discovered that nickel-plated brass far outperformed the other materials—including copper and brass. This current research sought to understand how antimicrobial properties of nickel-plating vary by plate thickness and substrate—in this case, brass and steel. Because test samples of varying nickel plating thickness were not readily available, this research had to first electroplate test samples with different thicknesses of nickel. Washer-shaped samples with different nickel-plating thicknesses were placed into petri dishes inoculated with E. coli bacteria. After six days of bacteria incubation, results showed that nickel-plated brass inhibited bacterial growth regardless of plating thickness, from 3 to 13µm. Antimicrobial properties were not limited to the nickel surface, but extended beyond a 5mm perimeter away from the surface. This research suggests that if nickel-plated brass were to replace steel and aluminum as touch surfaces in public spaces, there could be a global healthcare and economic benefit in the billions of dollars annually by eliminating touch surfaces as sources of contagion.

Independent Variable

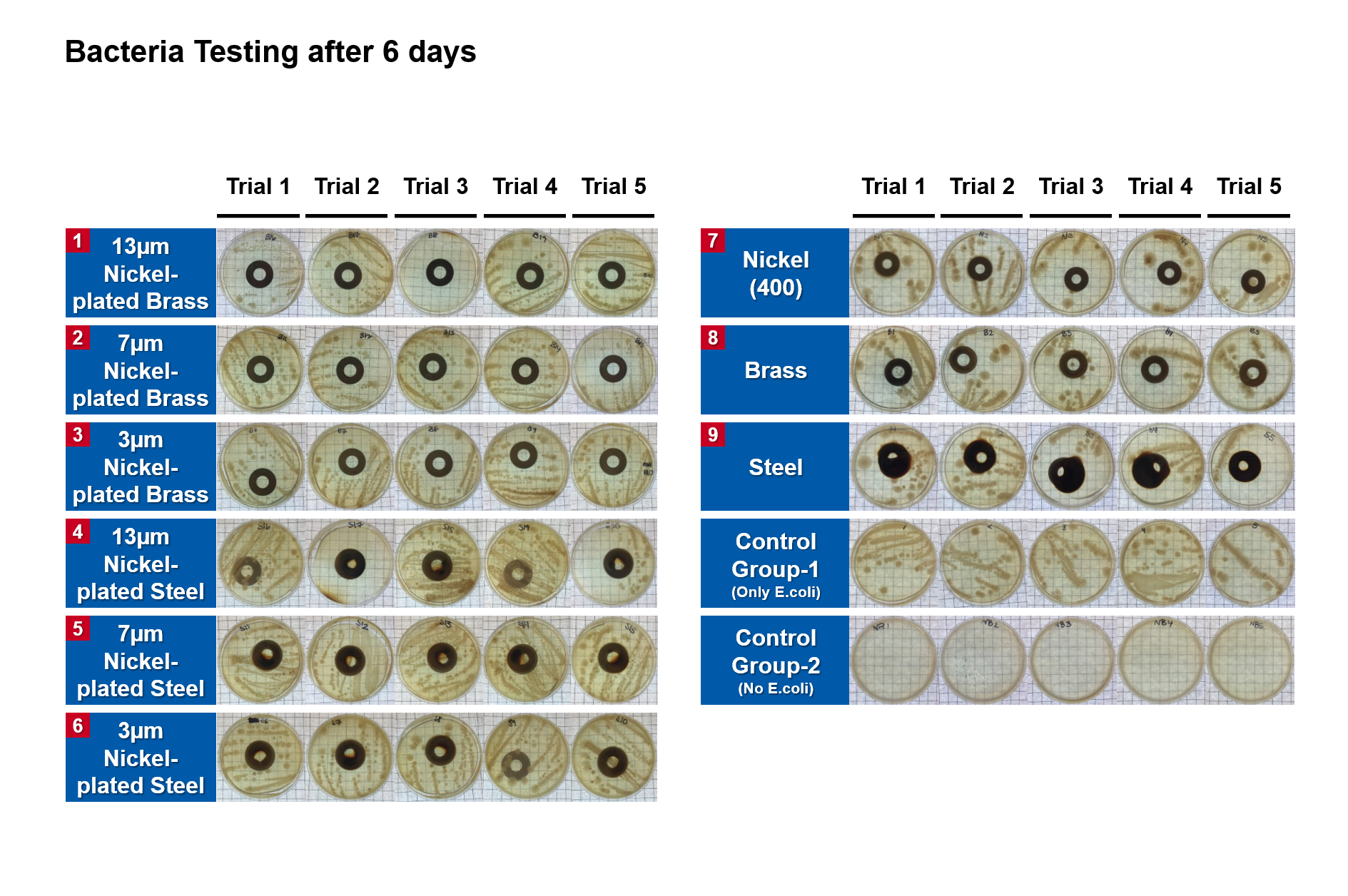

Material tested: nickel 400 (63% Ni, 31% Cu, 6% Fe), brass (Cu/Zn alloy), and steel; Thickness of nickel plating: 3 microns, 7 microns, and 13 microns

Dependent Variable

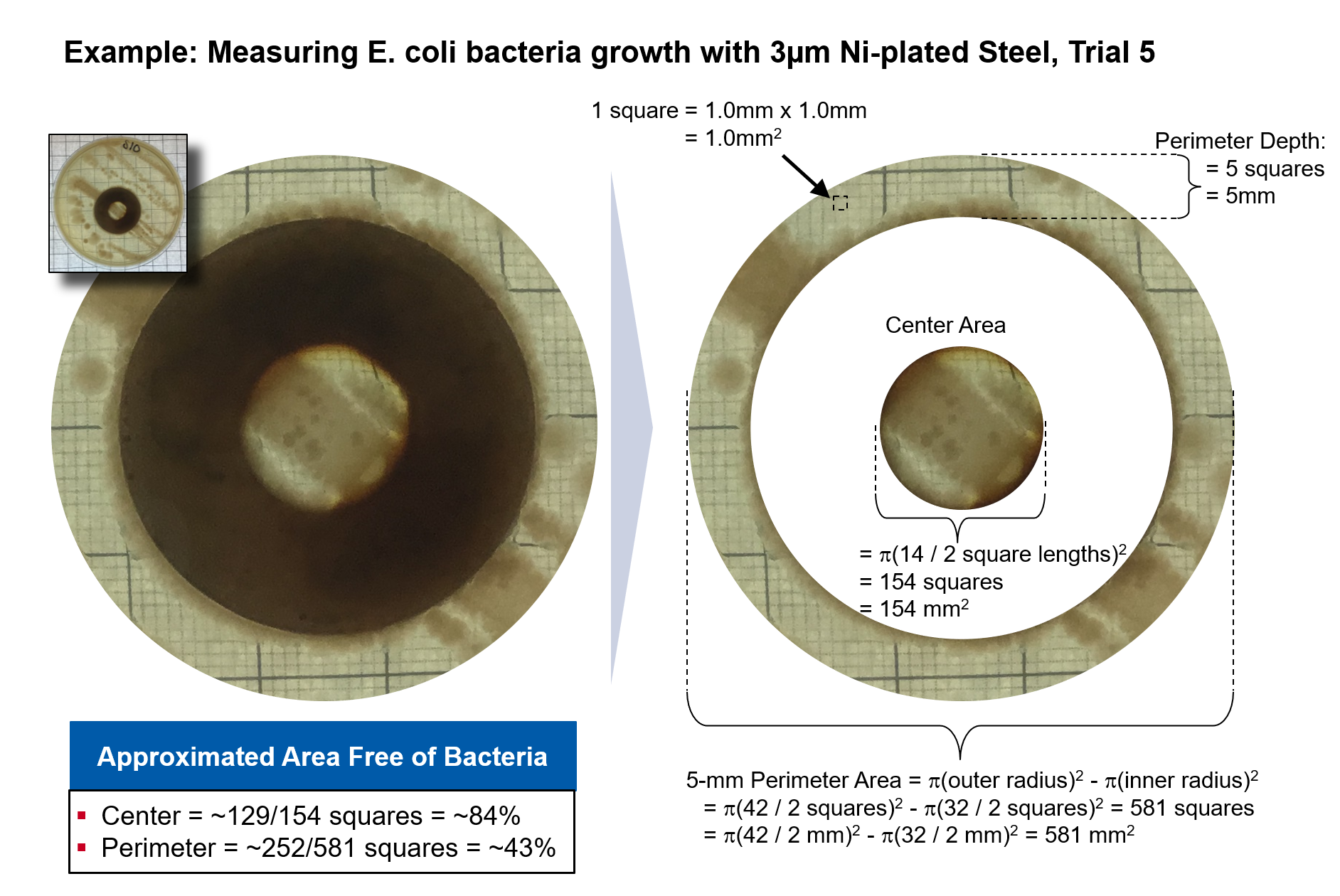

Percentage of washer inner diameter that is bacteria free after 6 days; Percentage of washer 5-mm outside diameter that is bacteria-free after 6 days

Controlled Variables

Type of bacteria (E. coli), testing chamber used, temperature of testing chamber, amount of bacteria swabbed on the petri dish, test time, approximate size of tested metals, temperature of the nickel electroplating solution, and current of the electroplating process

Photo Gallery

Data Collection

Results

Conclusion: Key Takeaways

• The antimicrobial advantage of nickel-plated brass over brass alone did not decrease as nickel plating thickness decreased from 13µm to 3µm

• Despite being more than 50% copper, brass under-performed nickel-plated brass in bacteria inhibition

• Nickel-plated brass demonstrated antimicrobial properties far superior to other materials tested

• Although Nickel 400 alloy contains 63% nickel and 31% copper, it under-performed both brass and nickel-plated brass in bacteria inhibition

• Steel proved unsuitable substrate for antimicrobial nickel plating because of susceptibility to corrosion

The Case for a Material that Fights Microbes

Annual cost of the Flu and Common Cold in the U.S.

>31 million doctor visits

>$10B in medical expenses

>200,000 hospitalizations

>$24B in lost wages

Between 3,000 & 49,000 deaths

>$100B in “total economic burden”

History Forgotten

• Egyptians used copper over 6000 years ago to sterilize wounds

• Due to purchasing cost considerations over the past 50 years, steel and plastics have largely replaced copper alloys for door knobs, handles, railings, buttons, and levers in public spaces